1. Main Purposes of The 16B Double-Sided Lapping/Polishing Machine:

What Double Side Lapping Machines can do?

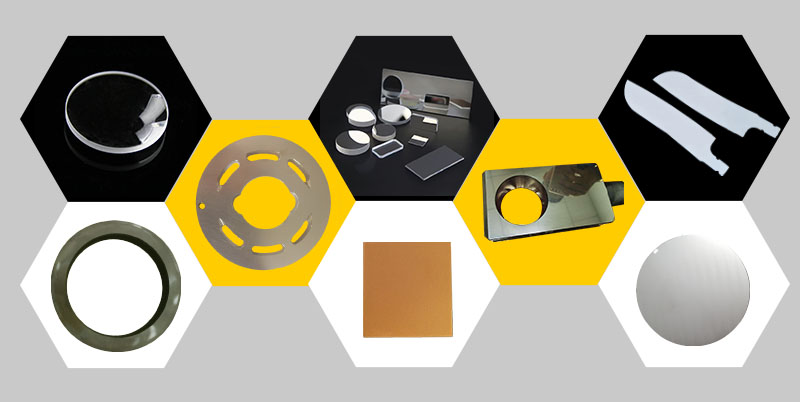

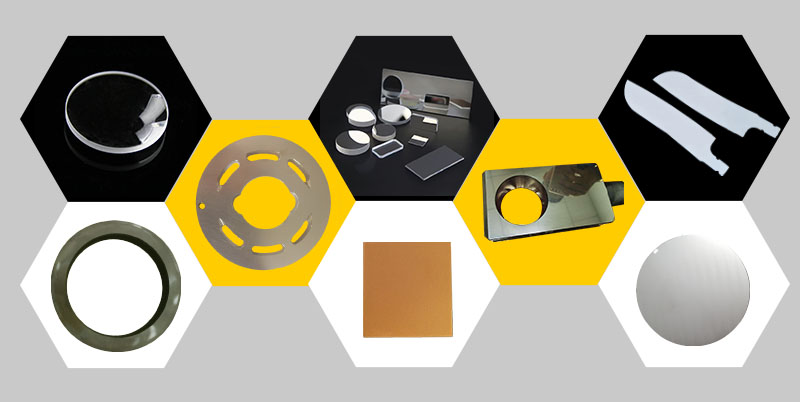

Applicable to thin hard and brittle materials such as metal sealing rings, sapphire, SiC, ceramics, glass grinding and polishing process, four-stage pressure control, to avoid damage to the processing of materials.

2. Technical Specifications of The 16B Double-Sided Lapping/Polishing Machine

|

Lapping plate diameter

|

φ1130*φ395*50 mm

|

|

Fixture (Star wheel) Diameter

|

φ405 mm

|

|

Maximum processing size

|

φ370mm

|

|

Workpiece thickness

|

0.3-30mm

|

|

Fixture (Star Wheel) Quantity:

|

5 SETS

|

|

Lower grinding disc speed

|

0-50rpm

|

|

Pressurized range

|

10-400KG

|

|

Main motor

|

YVP132M-4 7.5KW

|

|

Master cylinder

|

160*450

|

|

Press method

|

air cylinder pressure

|

|

Automatic thickness control

|

optional

|

|

Pressure control

|

two sections

|

|

Man-machine interface

|

optional

|

Machine size (mm)

|

1850*1480*2700mm

|

Machine weight

|

4,000 Kg

|

Applicable power supply

|

220V/380V

|

3. What Are The Advantages of 16B Double-Sided Lapping/Polishing Machine?

1). The fuselage adopts a gantry structure, with good rigidity, strong pressure bearing capacity, and stable operation at high speed.

2). The upper plate, lower plate and sun gear are separately driven by the motor.

3). The star wheel transmission adopts the structure of canceling ruler, and the transmission is stable and without impact.

4). During the descending process of the upper plate, fast descending and slow descending are adopted, and the slow descending speed can be adjusted.

5). This machine adjusts and controls the processing pressure through the precision electric proportional valve, and can set different processing pressures according to different processing requirements, and the pressure control precision is high.

6). Using PLC system, touch screen control panel, all process parameters and recipes can be modified and set on the touch screen, the equipment automatically completes the entire processing process according to the parameters.

4. Gears and Various Moving Parts Adopt Centralized Lubrication Device, Which Is Well Iubricated And Has A Long Service Life of The Whole Machine.

Main configuration:

1). Cylinder: AirTAC

2).Reducer: Chuanghong

3).Bearings: Ha, Wa, Luo

4). PLC: Siemens

5). Human-machine interface: Kunlun on-state

6). Electric proportional valve: AirTAC

7). Solenoid valve: AirTAC

8). Inverter: Bosch Rexroth

5. The Factory of Shenzhen Tengyu Grinding Technology Co., Ltd.

Shenzhen Tengyu Grinding Technology Co., Ltd. was located in Guangming New District, Shenzhen, China, with a registered capital of 5 million yuan, which plant area is about 13,000 square meters. It is an enterprise engaged in surface grinding and polishing technology. The company specializes in R&D, production and sales of various high-precision flat grinding equipment, flat polishing equipment, high-speed thinning equipment, 3D polishing equipment and its supporting consumables. Its products are widely used in precision processing of mechanical seals, electronic communications, ceramics, semiconductors, optical crystals, aerospace, automotive mold, LED, mobile phone accessories, hardware and other components. The customer base is spread all over the country and abroad, and its representatives include TF, MEEYA, Tongda Group, Hanslaser, and many other well-known companies.

6. FAQ

Q1: Are you trading company or manufacturer?

A: We're manufacturer. We have our own factory and experienced technicians.

Q2: What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3: What is your terms of delivery and delivery time?

A:EXW, FOB, CFR, CIF, DDU, etc. Generally, it will take 7 to 20 days after receiving your advance payment.The specific delivery time depends on the items and the quantity of your order.

Q4: Could you provide technology support?

A: We're in this field more than 20 years. If there's any problem, please contact with us, we'll provide suggestion from our engineer to help you solve problem.

Q5: What is the MOQ of customized products?

A: We are manufacturer and can provide you small MOQ for customized products.

Q6: Do you test all your goods before delivery?

A: Yes, every products will be test before delivery.

Q7: How do you make our business long-term and good relationship?

A.:We keep good quality and competitive price to ensure our customers’ benefit, and we respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Q8: Is there any quality guarantee?

A: We offer one year quality guarantee. We are responsible for the quality of our mechanical seals.

English

English  Esperanto

Esperanto  Беларус

Беларус  Shqiptar

Shqiptar  lugha ya Kiswahili

lugha ya Kiswahili  Bosanski

Bosanski  ជនជាតិខ្មែរ

ជនជាតិខ្មែរ  Кыргыз тили

Кыргыз тили  Монгол хэл

Монгол хэл  IsiXhosa

IsiXhosa  Точик

Точик  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  اردو

اردو  Ελληνικά

Ελληνικά  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақ

Қазақ  Euskal

Euskal  Azərbaycan

Azərbaycan  slovenský

slovenský  Српски

Српски  Română

Română