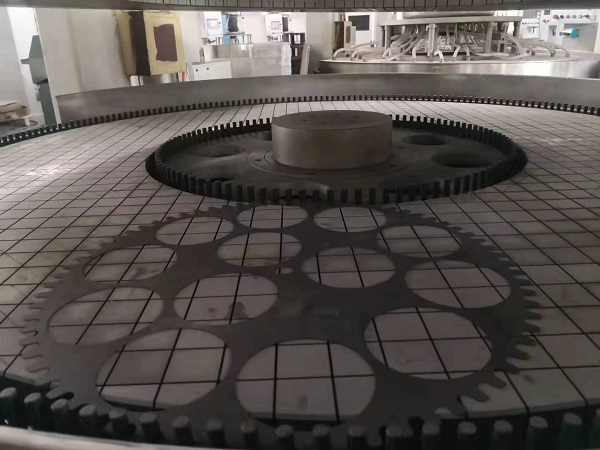

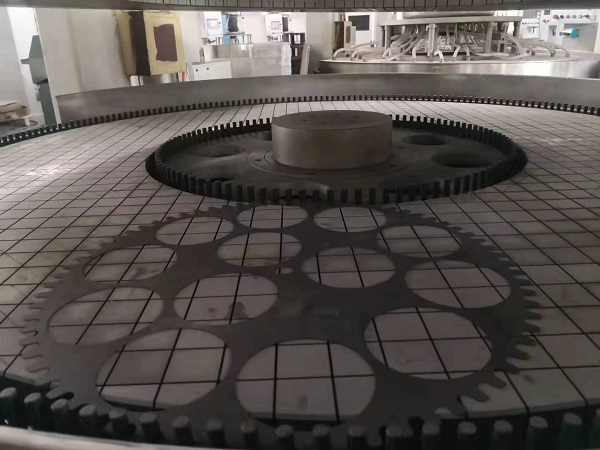

1. The Application of The Double Sided Polishing Machine for Optical Glass

Equipment Name: FD-15B Precision Double Sided Grinder

Equipment use: This machine is mainly used for semiconductor materials, optical glass, magnetic materials, dielectrics, piezoelectric materials, polycrystalline materials, non-polycrystalline materials,

High-precision grinding and polishing of ceramic sheets, ultra-thin metal materials and other hard and brittle materials.

2. Technical Parameter of The Double Sided Polishing Machine for Optical Glass

|

1

|

Lapping plate diameter

|

Ф1070XФ495X50mm

|

Material: HT250

|

|

2

|

Suspension System Weight

|

400kg

|

|

|

3

|

Maximum processing pressure

|

450kg

|

|

|

4

|

Upper grinding disc speed

|

5-40rpm

|

|

|

5

|

Lower grinding disc speed

|

5-50rpm

|

|

|

6

|

Fixture (Star Wheel) Quantity

|

7片

|

|

|

7

|

Fixture (Star wheel) size

|

P=16.84 Z =60 Ф321.66mm

|

|

|

8

|

ring gear

|

P=16.842 Z =206 Ф1100mm

|

Material: QT600-3A

|

|

9

|

Sun gear

|

P=16.842 Z =86 Ф465.4mm

|

Material: QT600-3A

|

|

10

|

Grinding thickness

|

Min: 0.4mm

|

|

|

11

|

Maximum processing size

|

Ф290mm

|

|

|

12

|

Lapping Plate drive

|

Independent speed regulation of upper and lower lapping plate

|

|

|

13

|

Ring gear to sun gear ratio

|

1 : 1.4

|

|

|

14

|

Lower plate motor power

|

11kw

|

|

|

15

|

Upper plate motor power

|

5.5kw

|

|

|

16

|

Equipment size

|

1956X1330X2300mm

|

|

|

17

|

Equipment weight

|

3600kg

|

|

3. Main Configuration of The of The Double Sided Polishing Machine for Optical Glass

|

|

Name

|

Brand

|

Mark

|

|

1

|

Main bearing

|

Harbin shaft/Wax shaft/Luo shaft

|

|

|

2

|

PLC

|

Delta / Omron / Yaskawa

|

|

|

3

|

Inverter

|

Delta / Omron / Yaskawa

|

|

|

4

|

Programmable HMI

|

Delta / Omron

|

|

|

5

|

Pneumatic Components

|

SMC/EMC/AirTAC

|

|

|

6

|

The electromagnetic valve

|

SMC/EMC/AirTAC

|

|

|

7

|

Reducer

|

Chuangri Precision / Chengda / Liming

|

|

|

8

|

Master cylinder

|

SMC/EMC//AirTAC

|

|

|

9

|

Safety hook cylinder

|

SMC/EMC//AirTAC

|

|

|

10

|

Ring gear lift cylinder

|

SMC/EMC//AirTAC

|

|

4. Electrical And Pneumatic General Parameters of The Double Sided Polishing Machine for Optical Glass

|

1

|

Main motor power

|

15kw

|

|

2

|

power supply

|

AC380V 50HZ

|

|

3

|

Gas source

|

0.4kg/㎝ 2 0.4Mpa

|

5. Parts List of The Double Sided Polishing Machine for Optical Glass

1) Random Tool: 1 SET

2) Manual: 1 SET

3) Liquid supply barrel: 1 SET

4) slurry pump: 1 SET

6. Primary Accuracy of The Double Sided Polishing Machine for Optical Glass

|

1

|

Mid-disk end-face beating

|

0.10mm

|

|

2

|

Ring gear radial runout

|

0.15mm

|

|

3

|

Ring gear end runout

|

0.15mm

|

|

4

|

The end face of the lowerPlate before grinding

|

0.15mm

|

|

5

|

The end face of the lowerPlate after grinding

|

0.10mm

|

|

6

|

Flatness ofPlate

|

0.10mm

|

7. The Factory of Shenzhen Tengyu Grinding Technology Co., Ltd.

Shenzhen Tengyu Grinding Technology Co., Ltd. was located in Guangming New District, Shenzhen, China, with a registered capital of 5 million yuan, which plant area is about 13,000 square meters. It is an enterprise engaged in surface grinding and polishing technology. The company specializes in R&D, production and sales of various high-precision flat grinding equipment, flat polishing equipment, high-speed thinning equipment, 3D polishing equipment and its supporting consumables. Its products are widely used in precision processing of mechanical seals, electronic communications, ceramics, semiconductors, optical crystals, aerospace, automotive mold, LED, mobile phone accessories, hardware and other components. The customer base is spread all over the country and abroad, and its representatives include TF, MEEYA, Tongda Group, Hanslaser, and many other well-known companies.

8. FAQ

Q1: Are you trading company or manufacturer?

A: We're manufacturer. We have our own factory and experienced technicians.

Q2: What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3: What is your terms of delivery and delivery time?

A:EXW, FOB, CFR, CIF, DDU, etc. Generally, it will take 7 to 20 days after receiving your advance payment.The specific delivery time depends on the items and the quantity of your order.

Q4: Could you provide technology support?

A: We're in this field more than 20 years. If there's any problem, please contact with us, we'll provide suggestion from our engineer to help you solve problem.

Q5: What is the MOQ of customized products?

A: We are manufacturer and can provide you small MOQ for customized products.

Q6: Do you test all your goods before delivery?

A: Yes, every products will be test before delivery.

Q7: How do you make our business long-term and good relationship?

A.:We keep good quality and competitive price to ensure our customers’ benefit, and we respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Q8: Is there any quality guarantee?

A: We offer one year quality guarantee. We are responsible for the quality of our mechanical seals.

English

English  Esperanto

Esperanto  Беларус

Беларус  Shqiptar

Shqiptar  lugha ya Kiswahili

lugha ya Kiswahili  Bosanski

Bosanski  ជនជាតិខ្មែរ

ជនជាតិខ្មែរ  Кыргыз тили

Кыргыз тили  Монгол хэл

Монгол хэл  IsiXhosa

IsiXhosa  Точик

Точик  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  اردو

اردو  Ελληνικά

Ελληνικά  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақ

Қазақ  Euskal

Euskal  Azərbaycan

Azərbaycan  slovenský

slovenský  Српски

Српски  Română

Română