1. Product Parameter of Dual Spindle Wafer Grinder

Equipment Name

|

Dual Spindle Wafer Grinder

|

Main Purposes

|

Mainly used to grind silicon carbide, silicon wafer, sapphire and other wafers

|

Process Description

|

The equipment can realize the integration of coarse grinding and fine grinding

|

Implementation Plan

|

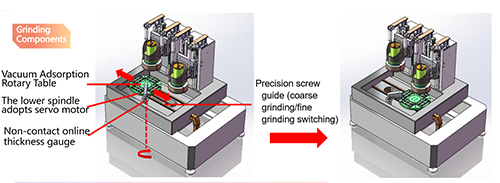

1. The position of the product on the lower spindle can be switched between coarse grinding and fine grinding.

2. The processing precision of the equipment is high, and the operation of the equipment is stable.

3. Use a non-contact measuring instrument to measure the thickness of the product.

|

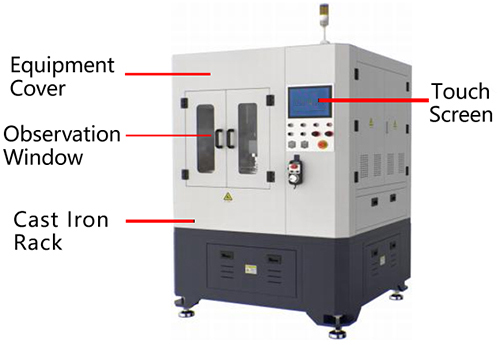

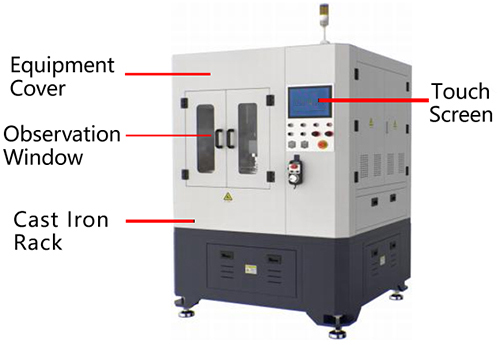

2. Product Feature of Dual Spindle Wafer Grinder

The outline and load-bearing structure adopt our latest cast iron frame, marble platform and support structure, and the support of the grinding wheel spindle is made of sand casting. Compared with the traditional weldment, this structure has higher strength and better precision. At present, foreign high-precision equipment has adopted this design.

Additional mist exhaust axial flow fan on the top

Innovation:

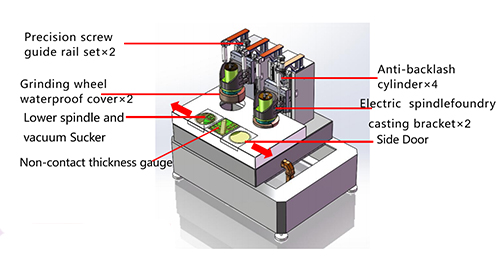

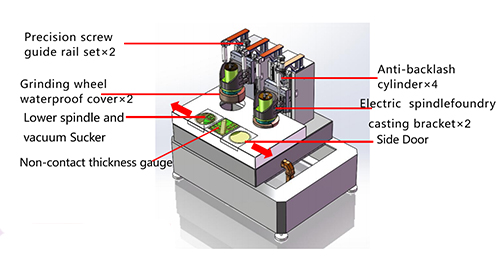

Compared with the conventional grinding machine, the anti-backlash cylinder group is added to eliminate the gap of the Screw and guide rail.

A grinding wheel waterproof cover and a second-layer waterproof cover are added to reduce the emission of a large amount of water mist during grinding.

Features:

The equipment can realize rough grinding and fine grinding at the same time.

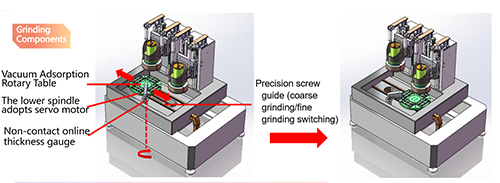

It adopts the fine grinding screw guide rail module and the vacuum Sucker spindle to switch back and forth between the rough grinding and fine grinding positions. It also has the function of non-contact online thickness gauge.

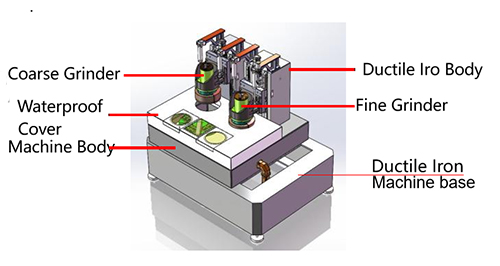

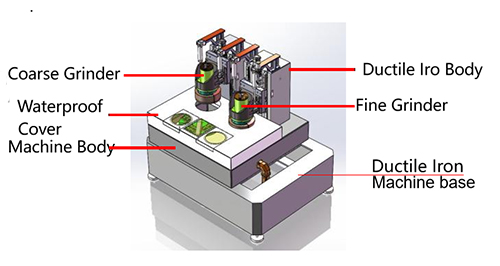

3. Product Structure of Dual Spindle Wafer Grinder

This machine is mainly composed of machine base, bed, vacum Sucker, Sucker spindle, grinding wheel spindle, grinding wheel feeding mechanism, online measurement system, control system, etc.

1. The base of the machine is made of ductile iron precision casting, and the body is made of high-rigidity marble, so that the accuracy can be maintained for many years,

2. The equipment adopts two grinding wheel spindles, which can realize coarse grinding and fine grinding at the same time.

3. Two 10-inch diamond grinding wheels are used, and the grain size of the grinding wheels can be selected according to product requirements.

4. The spindle of the Sucker moves left and right through the precision screw guide rail and the servo motor to realizocarse grinding and fine grinding.

5. Vacuum Sucker are customized according to product requirements.

6. The grinding wheel feed mechanism adopts THK precision screw rod, guide rail, Mitsubishi servo motor to drive the grinding wheel spindle to achieve fine grinding.

7. This machine adopts a non-contact online measuring instrument, the purpose is to measure the thickness of the product in a timely manner.

8. The control system adopts Mitsubishi PLC, servo motor, touch screen, etc.

Device Workflow

1. The equipment can store 20 sets of processing data of different products, which e can be called out directly when in use. New products need to reset the parameters and save them.

2. Processing flow: manually put the product into the designed vacum Sucker, set the final thickness of the product, coarse grinding thickness, fine grinding thickness, coarse grinding efficiency/second, fine efficiency/second, coarse grinding spindle torque. Fine grinding spindle torque. After the above data is set, start the button, and the equipment will start to work. During the working process of the equipment, it will automatically measure the thickness of the product for precise grinding. First, coarse grinding. After the coarse grinding is completed, the Sucker spindle will automatically transfer to the fine grinding. Completion of equipment automatic alarm to show that all work processes are completed.

You can contact us in the following ways:

Tel:+86 13622378685

Whatsapp:+86 13622378685

WhatsAPP Business: +86 13622378685

Web:www.lapping-machine.com

E-Mail:grace@lapping-machine.com

Add:Building 34, Yuanshan Industrial Zone B, Guangming, Shenzhen, China 518106

English

English  Esperanto

Esperanto  Беларус

Беларус  Shqiptar

Shqiptar  lugha ya Kiswahili

lugha ya Kiswahili  Bosanski

Bosanski  ជនជាតិខ្មែរ

ជនជាតិខ្មែរ  Кыргыз тили

Кыргыз тили  Монгол хэл

Монгол хэл  IsiXhosa

IsiXhosa  Точик

Точик  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  اردو

اردو  Ελληνικά

Ελληνικά  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақ

Қазақ  Euskal

Euskal  Azərbaycan

Azərbaycan  slovenský

slovenský  Српски

Српски  Română

Română