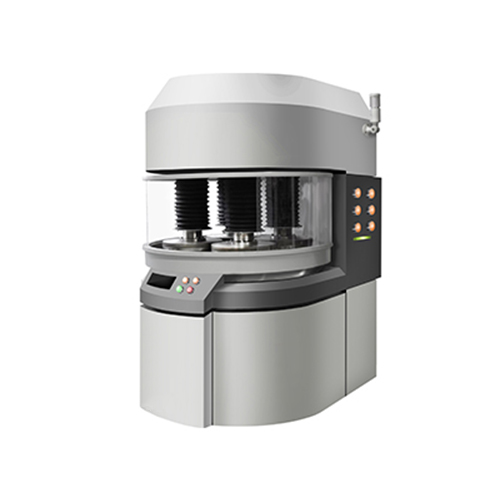

1. What The Sapphire Lapping And Polishing Process And Machines Can Do?

The Sapphire Lapping And Polishing Process And Machines is used for:

• Sapphire substrate/wafer

• Semiconductor wafer: silicon carbide, 12-inch silicon wafer, lithium tantalate, lithium niobate, etc.

• Tungsten carbide parts

• Ceramic parts

• Valves

• crystal glass

• Oscillator part

2. What Are The Advantages of The Sapphire Lapping And Polishing Process And Machines?

1). Sapphire Lapping and Polishing Process and machines with Lap plate correction device. It can ensure the high flatness of the grinding disc, and can also be grooved.

2). Each platen is controlled by an independent motor, with high grinding efficiency and good workpiece consistency after grinding.

3). The equipment is equipped with a chiller, which can cool the grinding disc and prevent the grinding disc from being deformed due to excessive temperature.

3. Technical Specifications of The Sapphire Lapping And Polishing Process And Machines:

|

Model

|

TY-7104XA

|

TY-9104XA

|

|

Plate material

|

Oxygen free Cu , Resin-Cu,Tin plate

|

Oxygen free Cu , Resin-Cu,Tin plate

|

|

Lap Plate Diameter

|

Φ710mm×φ200mm×12t

|

Φ910mm×φ200mm×12t

|

|

Block size

|

Φ300mm

|

Φ360mm

|

|

Maximum part Diameter

|

Φ260mm

|

Φ330mm

|

|

Plate cooling

|

Cooling water jacket

|

Cooling water jacket

|

|

P. Plate

|

4 axles.

(driving force system individually)

|

4 axles.

(driving force system individually)

|

|

Applied pressure

|

By cylinder

|

By cylinder

|

|

Capacity

|

4 inch wafer x 14 Pcs

6 inch wafer x 8 Pcs

8 inch wafer x 4 Pcs

|

4 inch wafer x 24 Pcs

6 inch wafer x 12 Pcs

12 inch wafer x4 Pcs

|

|

Plate Speed

|

0~60rpm

|

0~60rpm

|

|

Power of Main Motor

|

7.5KW /AC220V, 3Phase, 60Hz

|

7.5KW /AC220V, 3Phase, 60Hz

|

|

Pneumatic

|

0.5~0.8 Mpa

|

0.5~0.8 Mpa

|

|

Power of Surface Finishing Motor

|

0.2KW. 220V single phase

|

0.2KW. 220V single phase

|

|

Speed ofThe Lap plate correction device

|

0---120 mm/min

|

0---120 mm/min

|

|

Machine size

|

1150 *2050 *2200 mm

|

1350*2250*2300mm

|

|

Weight

|

2350kg

|

2500kg

|

|

Controller

|

Touch Screen (Proface)

|

Touch Screen (Proface)

|

4. The Factory of Shenzhen Tengyu Grinding Technology Co., Ltd.

Shenzhen Tengyu Grinding Technology Co., Ltd. was located in Guangming New District, Shenzhen, China, with a registered capital of 5 million yuan, which plant area is about 13,000 square meters. It is an enterprise engaged in surface grinding and polishing technology. The company specializes in R&D, production and sales of various high-precision flat grinding equipment, flat polishing equipment, high-speed thinning equipment, 3D polishing equipment and its supporting consumables. Its products are widely used in precision processing of mechanical seals, electronic communications, ceramics, semiconductors, optical crystals, aerospace, automotive mold, LED, mobile phone accessories, hardware and other components. The customer base is spread all over the country and abroad, and its representatives include TF, MEEYA, Tongda Group, Hanslaser, and many other well-known companies.

5. FAQ

Q1: Are you trading company or manufacturer?

A: We're manufacturer. We have our own factory and experienced technicians.

Q2: What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3: What is your terms of delivery and delivery time?

A:EXW, FOB, CFR, CIF, DDU, etc. Generally, it will take 7 to 20 days after receiving your advance payment.The specific delivery time depends on the items and the quantity of your order.

Q4: Could you provide technology support?

A: We're in this field more than 20 years. If there's any problem, please contact with us, we'll provide suggestion from our engineer to help you solve problem.

Q5: What is the MOQ of customized products?

A: We are manufacturer and can provide you small MOQ for customized products.

Q6: Do you test all your goods before delivery?

A: Yes, every products will be test before delivery.

Q7: How do you make our business long-term and good relationship?

A.:We keep good quality and competitive price to ensure our customers’ benefit, and we respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Q8: Is there any quality guarantee?

A: We offer one year quality guarantee. We are responsible for the quality of our mechanical seals.

English

English  Esperanto

Esperanto  Беларус

Беларус  Shqiptar

Shqiptar  lugha ya Kiswahili

lugha ya Kiswahili  Bosanski

Bosanski  ជនជាតិខ្មែរ

ជនជាតិខ្មែរ  Кыргыз тили

Кыргыз тили  Монгол хэл

Монгол хэл  IsiXhosa

IsiXhosa  Точик

Точик  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  اردو

اردو  Ελληνικά

Ελληνικά  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақ

Қазақ  Euskal

Euskal  Azərbaycan

Azərbaycan  slovenský

slovenský  Српски

Српски  Română

Română