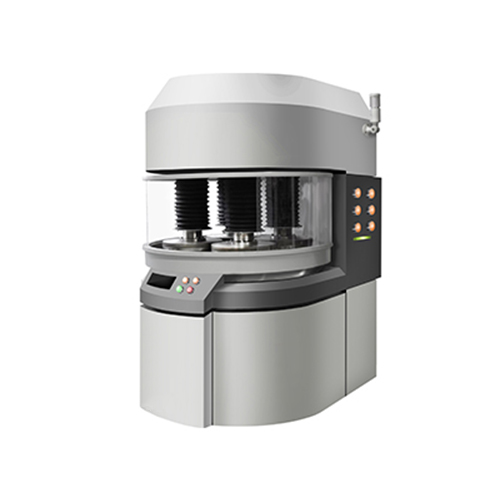

Lapping machine is a kind of equipment to improve the surface flatness and roughness of products. It is divided into single-sided lapping machine and Dual Face Lapping Machine. Single-sided lapping machine can only grind one side, while Dual Face Lapping Machine can grind two sides at the same time.Lapping machine was used in mechanical seals, aerospace, mobile phone electronic communications, semiconductor industry, metal and other industries. It has good grinding effect on stainless steel, tungsten steel, cemented carbide, zinc alloy, aluminum alloy, high temperature alloy, optical glass, ceramics, silicon wafer, silicon carbide, quartz and other materials.

Tengyu is a lapping machine manufacturer which specializing in the R&D and production. It is a high-quality manufacturer in China, with a production workshop of 6000 square meters, an office area of 2000 square meters ,a strong technical team and perfect after-sales service system.

The lapping machine produced by Tengyu has the following advantages:

1). With automatic lapping plate correction device, it can ensure the high flatness of the plate, and can also ensure that the workpiece has a high flatness after grinding;

2). It can be used for grinding or polishing, and the roughness after polishing can reach nanometer level.

3). It is a semi-automatic equipment. Except for manual loading and unloading, other operations can be performed automatically according to the parameters set on the control panel. This saves labor and improves efficiency.

4). The lapping machine sold by Tengyu is fully equipped, easy to operate, and can provide video teaching.

5). All accessories and consumables can be produced by Tengyu, and they are provided in complete sets, so there is no need to find other relevant suppliers.

English

English  Esperanto

Esperanto  Беларус

Беларус  Shqiptar

Shqiptar  lugha ya Kiswahili

lugha ya Kiswahili  Bosanski

Bosanski  ជនជាតិខ្មែរ

ជនជាតិខ្មែរ  Кыргыз тили

Кыргыз тили  Монгол хэл

Монгол хэл  IsiXhosa

IsiXhosa  Точик

Точик  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  اردو

اردو  Ελληνικά

Ελληνικά  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақ

Қазақ  Euskal

Euskal  Azərbaycan

Azərbaycan  slovenský

slovenský  Српски

Српски  Română

Română