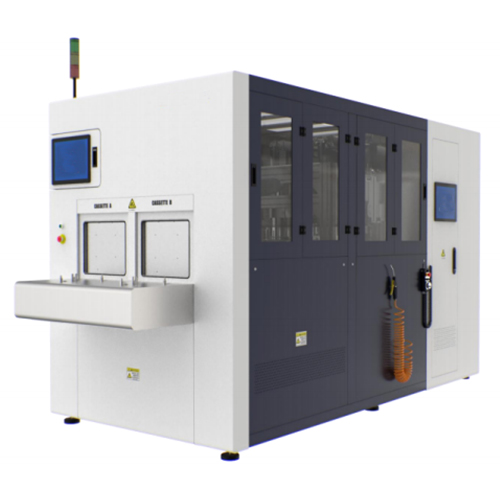

Wafer Grinder are used in the semiconductor industry, which can quickly thin wafers, and can also be used to thin other ultra-thin materials. Such as silicon wafers, silicon carbide, sapphire, gallium arsenide, gallium nitride, ceramics, lithium tantalate, lithium niobate, indium sulfide, barium titanate, molding compound, chips, etc.

The advantages of the wafer grinder produced by Tengyu:

1). High roduction efficiency, the maximum grinding wheel speed can reach 3000rpm;

2). The thickness of 2.6-inch wafer can be 60um;

3). The thickness can be effectively controlled, and the thickness tolerance can be controlled within ±0.005;

4). Flatness and parallelism are much higher than ordinary grinders;

5). The program is precisely controlled and the operation is simple.

6). Vacuum adsorption, the product is firmly fixed and not easy to be broken.

Wafer grinder are divided into two types: semi-automatic and fully automatic. Among them, there are many models of semi-automatic, including basic models, air-floating spindle models, dual-axis models, and single-axis models, each with different functions and accuracy. If you need it, please consult our customer service in detail to confirm the most suitable model for you.

The wafer grinder produced by Tengyu has been put on the market for many years. Due to its wide application, the thinned products have high precision, long service life and low failure rate, and have won unanimous praise from customers.

We are a manufacturer of wafer grinder in China, and our wafer grinders are exported to Malaysia, Singapore, Indonesia, Thailand, South Korea, Taiwan, Russia and other countries.

English

English  Esperanto

Esperanto  Беларус

Беларус  Shqiptar

Shqiptar  lugha ya Kiswahili

lugha ya Kiswahili  Bosanski

Bosanski  ជនជាតិខ្មែរ

ជនជាតិខ្មែរ  Кыргыз тили

Кыргыз тили  Монгол хэл

Монгол хэл  IsiXhosa

IsiXhosa  Точик

Точик  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  اردو

اردو  Ελληνικά

Ελληνικά  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақ

Қазақ  Euskal

Euskal  Azərbaycan

Azərbaycan  slovenský

slovenský  Српски

Српски  Română

Română